Packaging lines are designed for maximum efficiency, but like a chain, they’re only as strong as their weakest link. A single breakdown can disrupt the entire operation, leading to costly downtime — the ultimate enemy of productivity.

That’s why strategic planning is essential when upgrading your line. With proper preparation, you can minimize disruptions, maintain peak efficiency and even enhance performance by integrating the latest innovations from Serpa.

Even the best-maintained equipment will eventually need repairs or replacement. Choosing the right packaging line manufacturer can make all the difference, ensuring a seamless transition with minimal downtime.

Serpa leads the industry with an impressive 98% uptime guarantee, making it the go-to choice for upgrading automated packaging lines. Keep reading to discover when it’s time for your next equipment upgrade!

Signs It’s Time to Upgrade Equipment in Your Packaging Line

Excessive Downtime Due to Maintenance Issues

More maintenance issues mean more downtime, and as packaging equipment ages, upkeep becomes more frequent, directly impacting efficiency.

No matter how well-built or maintained a machine is, wear and tear inevitably lead to increased servicing needs, putting your production line at risk of costly slowdowns.

Serpa tackles this challenge head-on with meticulously designed automated packaging machines that prioritize easy maintenance access. Our innovative solutions maximize uptime by ensuring that wear parts and key service points are easily reachable, allowing technicians to complete maintenance quickly and efficiently.

With Serpa, you get the reliability you need to keep your line running at peak performance.

Lengthy and Complicated Changeovers

Modern packaging operations demand flexibility and rapid changeovers. Serpa meets these needs with toolless changeovers for grids and ergonomically designed change parts, ensuring effortless adjustments for maximum efficiency.

By eliminating the need for specialized tools or proprietary components, Serpa empowers technicians to work faster and more efficiently, helping maintain our industry-leading 98% uptime.

Inability to Meet Production Demands

Industrial automation is constantly evolving, and it’s easy for packaging line equipment to become outdated, especially if your line is still meeting demand. However, as machinery ages, efficiency gradually declines while maintenance demands increase, leading to more downtime and higher costs.

Instead of battling a losing war against wear and tear, upgrading your equipment can be the smarter, more cost-effective choice. With Serpa’s industry-leading 98% uptime guarantee, you can modernize your packaging line without sacrificing productivity, ensuring seamless performance and long-term efficiency.

Rising Labor Costs

Labor costs have long been a challenge in the manufacturing industry, and rising wages are making profit margins even tighter. Serpa designs automated packaging machines with this in mind, minimizing the need for human input in both operation and maintenance.

A prime example is Serpa’s integrated high-speed insert and tray loading system, which reduces staffing requirements by automating insert feeding. Trays of inserts are cut, unloaded and advanced automatically, eliminating the need for a dedicated operator.

Additionally, Serpa machines feature easy-to-change grids parts, allowing operators to handle changeovers independently without the need for extra personnel or the risk of overhead strain or injury.

For many businesses, investing in advanced automation is not only a way to cut labor costs but also a necessity for meeting increasingly stringent industry standards. With Serpa’s high-efficiency solutions, you can optimize your packaging line while keeping operational costs in check.

Difficulty Meeting Current Industry Standards

Industry standards are constantly evolving, driven by advancements in technology, safety and quality assurance. From stringent cleanliness requirements in the food and pharmaceutical industries to the increasing demand for standardization, meeting compliance benchmarks has never been more critical.

Packaging line automation simplifies the process, ensuring consistency and precision that manual operations simply can’t match. With Serpa’s expertise in pharmaceutical regulations, sterilization and high-performance packaging, you can trust that your automated packaging line meets the highest industry standards.

Whether you’re packaging pharmaceutical vials, syringes, or blister packs, Serpa delivers reliability, efficiency and compliance — all in one seamless solution.

Poor Ergonomics and Safety Concerns

Worker safety is a top priority in modern manufacturing, and every effort should be made to create a safe, comfortable work environment. Serpa takes this commitment seriously by designing packaging machines with ergonomics and user well-being in mind.

Every machine in Serpa’s lineup is engineered to reduce strain and support proper posture, minimizing the risk of workplace injuries over time. Thoughtful design elements ensure that operators can work efficiently and comfortably, helping to create a safer, more productive environment.

How to Plan Your Packaging Line Optimization

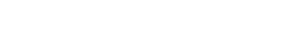

Knowing it’s time to upgrade is one thing — deciding when to do it is another. The key to a seamless transition is careful planning to minimize downtime and disruption.

A phased approach is often the best strategy. Instead of shutting down your entire line for a full replacement, consider upgrading one component at a time. This method allows you to assess how new equipment integrates with existing processes while steadily improving efficiency.

Serpa makes the transition even easier with fully integrated packaging line solutions. Whether you’re incorporating Serpa machines into an existing setup or working with equipment from multiple manufacturers, our expertise in seamless packaging line integration ensures your operation runs at peak performance with minimal hassle.

Boost Packaging Line Efficiency With Serpa

The Serpa team is ready to help you take your packaging line to the next level. Start with a comprehensive assessment, and we’ll identify key upgrades to enhance efficiency, boost ROI and maintain our industry-leading 98% uptime guarantee.

Don’t let outdated equipment slow you down. Contact our experts today and take the first step toward a more optimized, high-performance packaging line!